What Are The Biggest Problems With Fluorocarbon?

The use of fluorocarbon has grown tremendously in the past 10 years to now become the most popular line in the bass fishing market. It started as a leader material to be used with braided lines. As the fluorocarbon lines improved, anglers have utilized them more as their top choice for a mainline. There are many benefits that fluorocarbon offers that have contributed to why it has become so popular, but what are the problems with fluorocarbon? This article breaks down the five biggest challenges of using fluorocarbon.

Cost

The first problem with fluorocarbon is its cost. Fluorocarbon lines have a retail price that is often 2X-3X higher than nylon(monofilament) lines. The higher retail cost directly results from the fluorocarbon raw materials being more expensive than nylon options. This higher cost can be compounded if you are a new angler or an angler that backlashes frequently. Having to cut out a backlash after making an errant cast becomes much more costly when using fluorocarbon.

Knots

The second challenge with utilizing fluorocarbon lines can be break offs on hook sets. With traditional nylon lines, almost any knot will work effectively. Fluorocarbon is a much harder material, and with some knots, or knots that are tied improperly, the line will actually cut itself on a hard hookset. This can be a big problem when utilizing popular techniques like pitching. The key is to select a knot like the 3-tag, San Diego Jam, or Tornado HH Knot, which tests out as one of the best knots for fluorocarbon. See more knots here. This article has more details about why the Tornado HH Knot is the best knot for fluorocarbon.

Stiffness

The third challenge with fluorocarbon is that it is harder and stiffer than nylon lines of the same lb test. This makes it a bit harder to cast with baitcast reels and can also cause it to want to “jump off” spinning reels. This stiffness prevents the line from lying on a reel as easily, which can make it harder to cast and manage on both types of reels. When doing repetitive casting, you can easily tell the difference between the performance of a stiffer and softer line. This article provides suggestions on how to prevent backlashes.

Kinks

Line kinks can often happen when using baitcasting reels, which makes up the fourth challenge of fluorocarbon. Kinks happen when the line passes under itself or the spool overruns on a cast. Kinks caused by those circumstances and the corresponding actions to remove them can cause additional kinks. Those kinks create a weak point in fluorocarbon lines, much like “scoring glass ahead of breaking it,” and will cause the line to break randomly in the future.

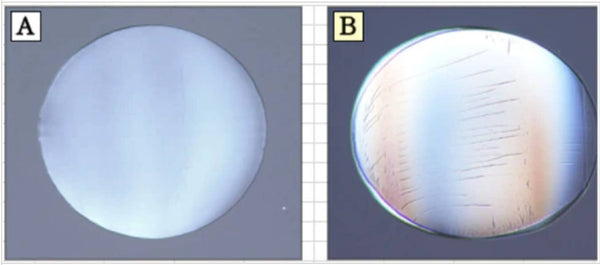

Below, a cross-section image of two lines is seen under an electron microscope. Line A is a normal fluorocarbon line that you can see has no defects. Line B shows an image of the same line where it had been kinked. You will see in image B that micro-cracks are now visible inside the line at the spot where it was kinked. Those micro-cracks weaken the line and lower its overall performance.

Sinks

The final characteristic of fluorocarbon that can be problematic is that it sinks. Water has a specific gravity of 1, whereas fluorocarbon has a specific gravity of 1.78, meaning it will sink. This can be a benefit for making lines run deeper, but it can be a problem when used with lures like topwaters. The sinking nature of fluorocarbon will pull down the nose of a topwater lure and prevent it from having its best performance. This video quickly shows the specific gravity of fluorocarbon, nylon, and braid.